English

| Availability: | |

|---|---|

| Quantity: | |

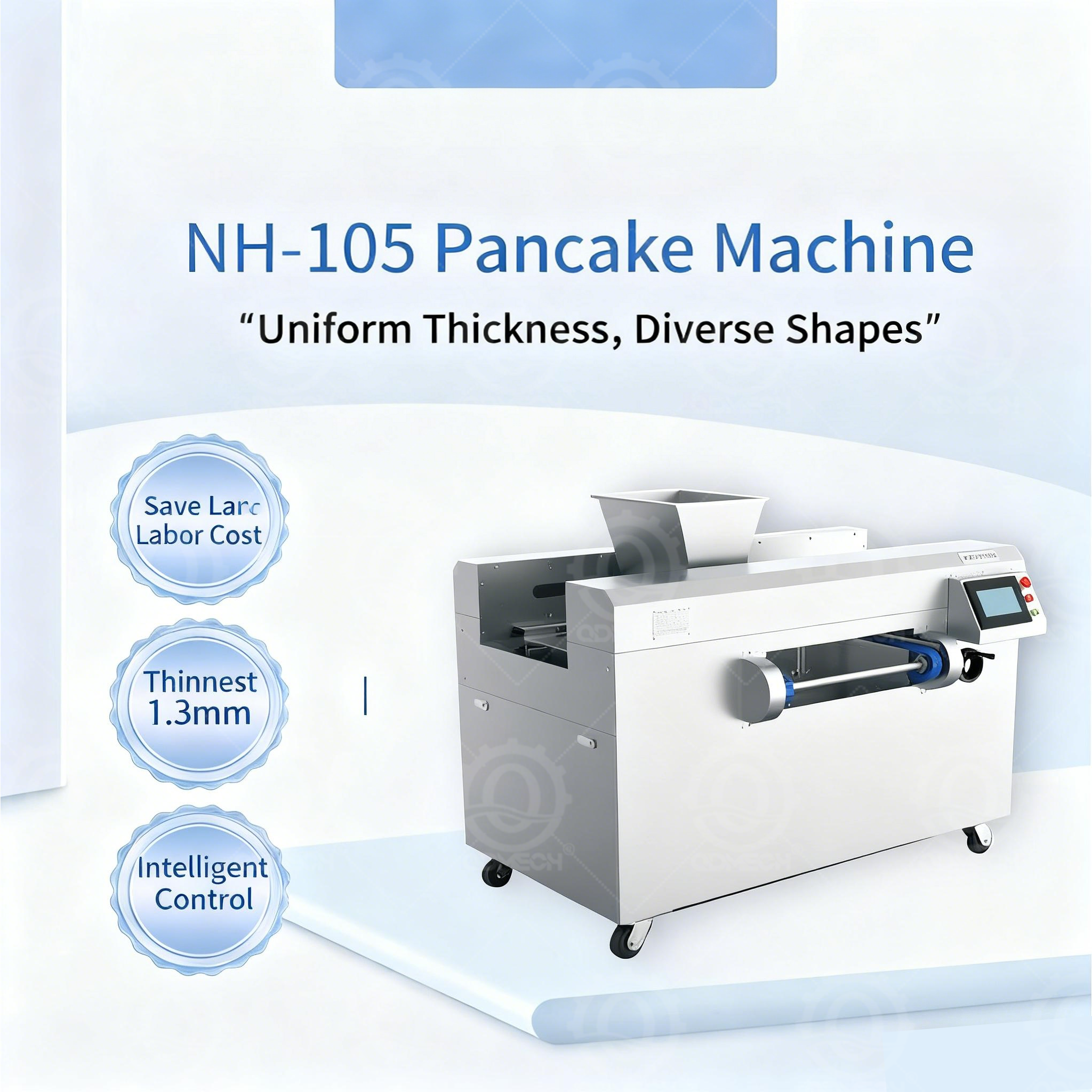

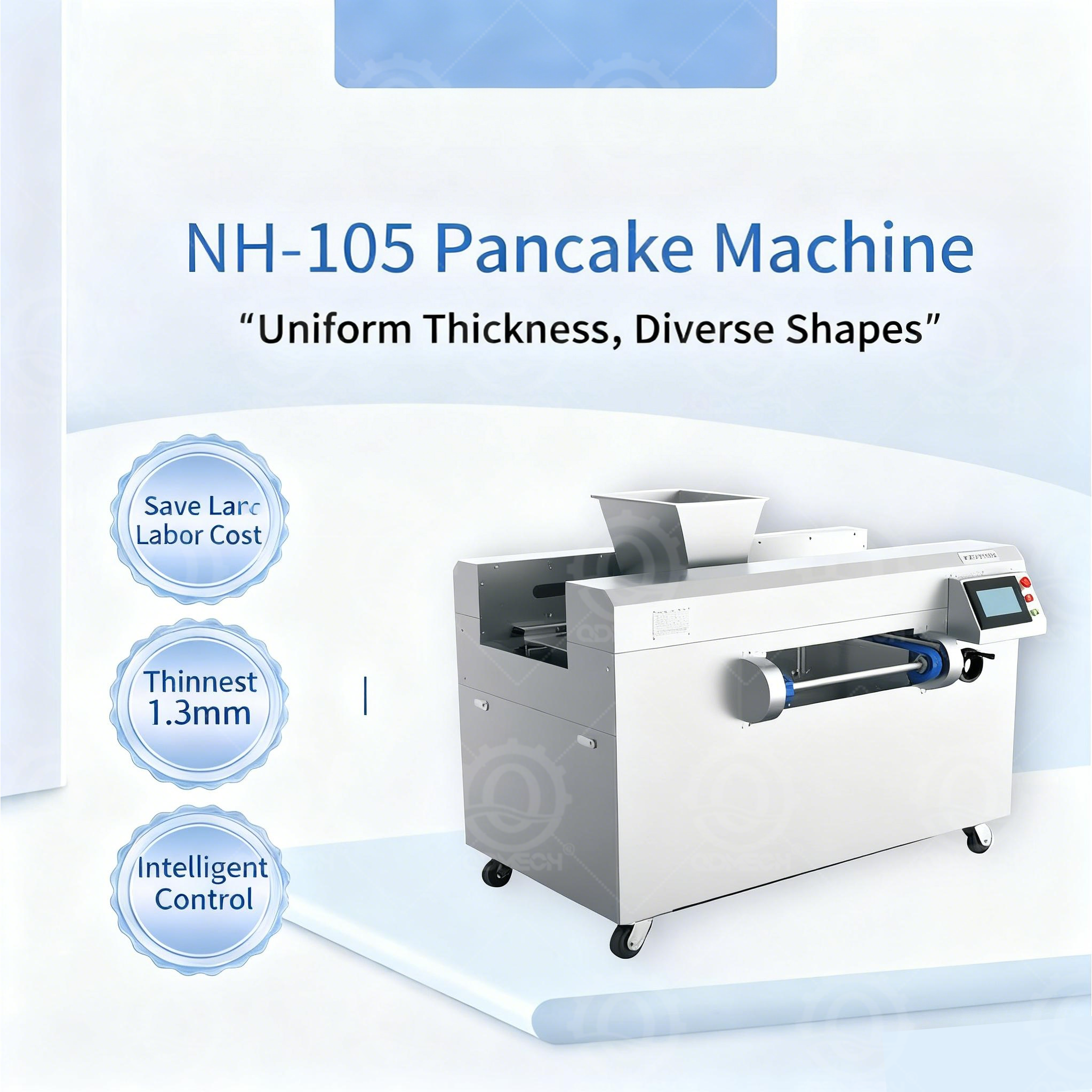

NH-105

QDMECH

HN-20251202-01

1.High Efficiency & Intelligence: Production capacity of 300-400 trays per hour, featuring intelligent control + mold forming. Adjustable thickness from 1.3-10mm ensures uniform product thickness.

2.Flexible and Convenient: Rapid mold change within 5 minutes, supports custom template shapes, and integrates into production lines for automated mass manufacturing;

3.Reliable Quality: Constructed with 304 stainless steel, featuring premium components like Mitsubishi PLC and Weintek touchscreens. CE certified with a 1-year warranty, ensuring simple operation and durability.

The NH-105 Commercial Pancake Machine,Biscuit Making Equipment, constructed from 304 stainless steel, operates at 220V voltage and 1000W power, delivering a production speed of 300-400 pans per hour. It comes equipped with 2 sets of molds as standard accessories, has a net weight of 400kg, and features external dimensions of 156012001300mm.

Product Name | Biscuit Making Equipment |

Brand and Model | NH-105 |

Voltage | 220V |

Power | 1000W |

Speed | 300-400pan/hr |

Standard Accessories | 2 sets of molds |

Net Weight | 400kg |

Machine Size | 1560*1200*1300mm |

Material | Stainless steel 304 |

The wafer and cracker production machine is constructed from food-grade 304 stainless steel, representing a high-efficiency industrial-grade device primarily suited for large-scale continuous wafer production in food processing plants, commercial bakeries, and snack production facilities. With an hourly production capacity of 300-400 trays, it meets high-volume wafer manufacturing demands. Equipped with two interchangeable molds, it can produce standard wafers or customize various wafer types, fulfilling food enterprises' requirements for high output, stable production, and diverse manufacturing needs.