English

| Availability: | |

|---|---|

| Quantity: | |

QDMECH

HN-20251128-02

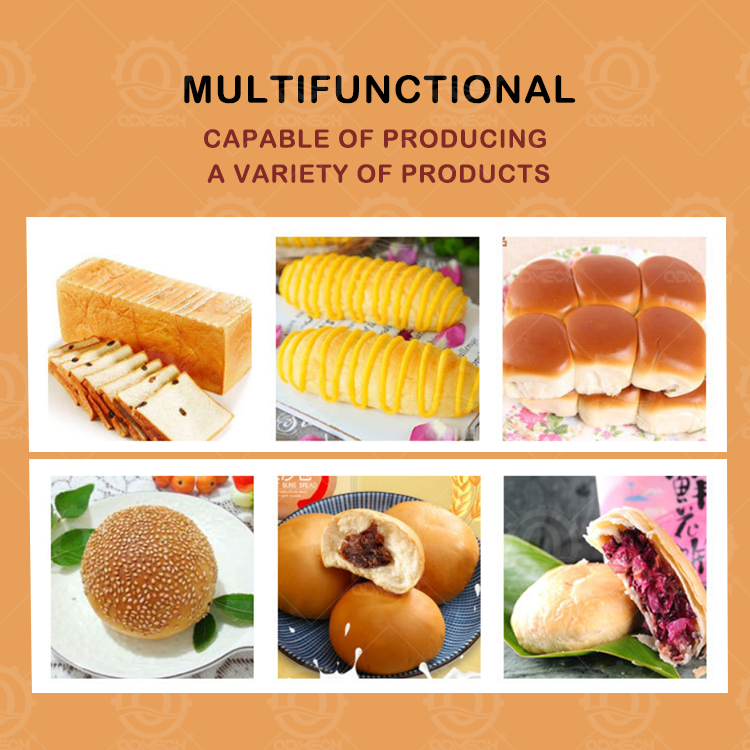

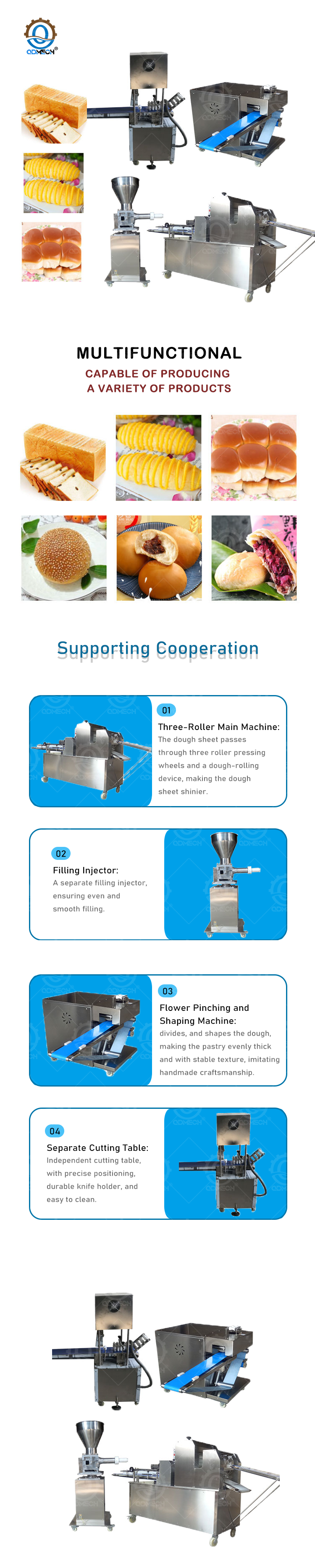

1.Three-Roller Main Machine: The dough sheet passes through three roller pressing wheels and a dough-rolling device, making the dough sheet shinier.

2. Filling Injector: A separate filling injector, ensuring even and smooth filling.

3. Flower Pinching and Shaping Machine: The pinching machine closes, divides, and shapes the dough, making the pastry evenly thick and with stable texture, imitating handmade craftsmanship.

4. Separate Cutting Table: Independent cutting table, with precise positioning, durable knife holder, and easy to clean.

The bread production line originates from Henan, China. It is an integrated food processing system constructed from 304 stainless steel, comprising three bread main units (13500×880×1350 mm), a rotary hopper filler (500×650×1450 mm), a new six-slice molding machine (900×750×850 mm), and an independent cutting station (1500×750×850mm). Operating at 380V with a rated power of 1.5kW, the equipment enables end-to-end bread production. Specifically designed for bakery and pastry processing plants, it ensures efficient and standardized bread production processes.

Product name | Bread Production Line | |||

Machine name | Three-loaf bread production main machine | Round hopper filling machine | New six-slice shaping machine | Independent cutting table |

Product size | 13500×880×1350mm | 500×650×1450mm | 900×750×850mm | 1500×750×850mm |

Power | 1.5kw | |||

Voltage | 380v | |||

Function | Full-line bread production | |||

Application | Bread and Cake Processing Factory | |||

Material | 304 Stainless steel | |||

place of origin | Henan, China | |||

The automatic toast bread production line is suitable for commercial bakeries, food processing factories and bakery chains, covering the whole process from dough processing, shaping to baking. It supports adjustable bread specifications, improves production efficiency and ensures consistent product quality, meeting diverse market demands for bread.