English

| Availability: | |

|---|---|

| Quantity: | |

QDMECH

HN-20260116-02

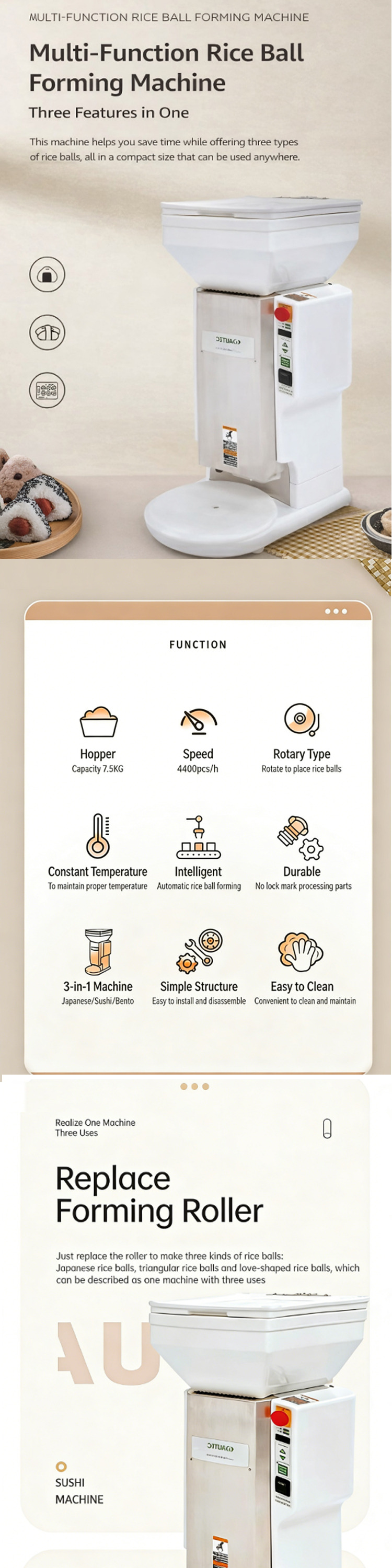

The Professional Multifunctional 3 in 1 Rice Ball Forming Machine is an industrial 3 in 1 Rice Ball Forming Machine designed for efficient shaping, forming, and portioning of rice balls in commercial kitchens, catering operations, and food production lines. With high-capacity feeding, precision forming molds, and adjustable output sizes, this 3 in 1 Rice Ball Forming Machine streamlines production and reduces labor costs. The unit’s intuitive control panel and durable construction support continuous, reliable operation in industrial food processing environments, improving consistency and throughput.

This 3 in 1 Rice Ball Forming Machine integrates rice feeding, shaping, and output stacking in one compact unit. The multifunctional design minimizes manual labor, accelerates production, and enhances output uniformity compared to standalone forming equipment. B2B buyers benefit from faster line speeds and reduced workforce requirements in commercial kitchens and food processing plants.

Equipped with interchangeable molds and adjustable forming mechanisms, this machine supports various rice ball sizes and shapes. Industrial-grade components ensure consistent portioning accuracy, enabling food processors to meet volume targets and customer specifications. The high-capacity feeding system ensures uninterrupted production even during peak demand.

Manufactured with high-strength stainless steel, the machine resists corrosion and supports frequent cleaning in food environments. The rugged build ensures that this Industrial 3 in 1 Rice Ball Forming Machine delivers long service life and reliable performance under continuous operation, minimizing maintenance downtime.

The machine features a user-friendly control panel with clear buttons and adjustable parameters for speed, mold count, and portion size. Operators of varying skill levels can quickly learn to control the system, reducing training time and enhancing operational uptime, even for facilities that also handle unrelated products like an Electric Wooden Digital Piano in their showroom or staff break areas.

Designed with food-grade materials and safety interlocks, this Multifunctional 3 in 1 Rice Ball Forming Machine meets international hygiene standards. Smooth surfaces and removable parts simplify cleaning and sanitization processes, supporting efficient adherence to food safety protocols in commercial kitchens and export food manufacturing facilities.

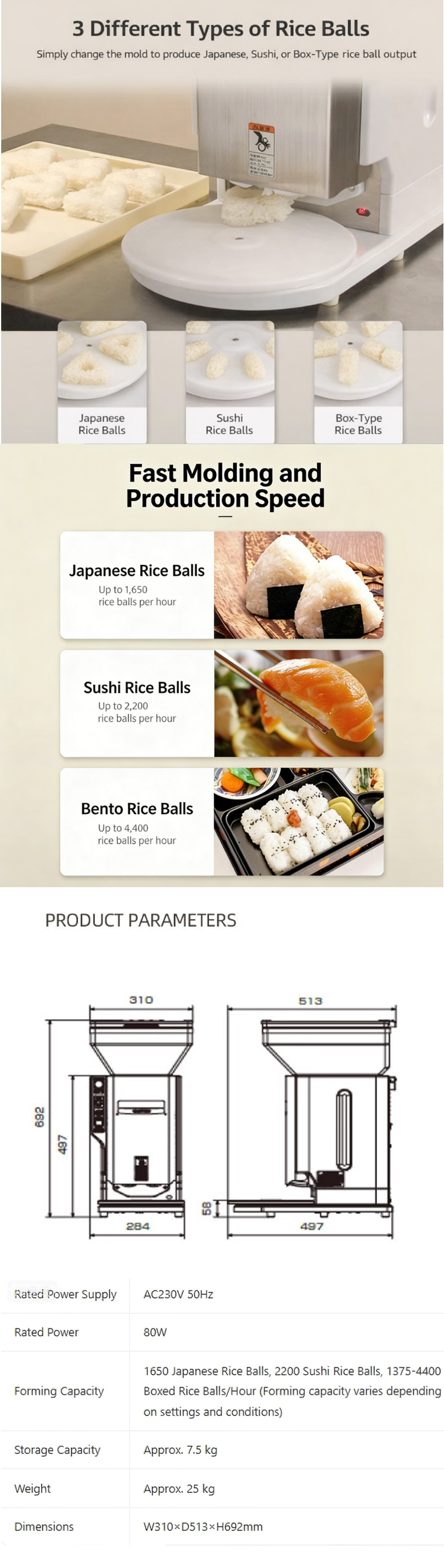

The technical parameters of the rice ball forming equipment are as follows: it adopts an AC220V 50Hz rated power supply, has a rated power of 80W, and features a forming capacity of 1650 Japanese rice balls, 2200 sushi rice balls, or 1375-4400 boxed rice balls per hour (note that the forming capacity varies depending on specific settings and working conditions); the equipment has a storage capacity of approximately 7.5 kg, a net weight of around 25 kg, and overall dimensions of 310×513×692mm.

Rated Power Supply | AC220V 50Hz |

Rated Power | 80W |

Forming Capacity | 1650 Japanese Rice Balls, 2200 Sushi Rice Balls, 1375-4400 Boxed Rice Balls/Hour (Forming capacity varies depending on settings and conditions) |

Storage Capacity | Approx. 7.5 kg |

Weight | Approx. 25 kg |

Dimensions | W310×D513×H692mm |

In high-volume catering facilities, this 3 in 1 Rice Ball Forming Machine delivers consistent portioning and reduces labor intensity. Operators can switch molds to produce different rice ball sizes for buffet lines, banquet services, or packaged meals, improving kitchen throughput and food presentation quality.

For food manufacturers producing pre-packaged rice balls, this industrial forming machine integrates into production lines with conveyors and packaging systems. Its high forming accuracy and sanitary design reduce waste and support compliance with food safety and export standards required by global distributors.

Restaurant chains and franchises benefit from standardized output quality and reduced preparation time, enabling consistent menu delivery across multiple outlets. The machine’s simple interface and low maintenance make it suitable for fast-paced kitchen environments without requiring specialized technicians.

Schools and institutional dining facilities serving large populations can leverage this Professional 3 in 1 Rice Ball Forming Machine to produce rice balls efficiently for daily menus. Its robust construction and easy cleaning support compliance with hygiene standards, while reliable performance reduces meal preparation bottlenecks.

Q1: What is the forming capacity of this 3 in 1 Rice Ball Forming Machine?

A1: Capacity depends on mold size and production settings, typically ranging from 1,000+.

Q2: How easy is the machine to clean and maintain?

A2: The unit is made from food-grade stainless steel with removable forming parts, allowing quick disassembly and cleaning. Regular sanitation helps maintain food safety and machine longevity.

Q3: Can the molds be customized for different rice ball shapes?

A3: Yes. Interchangeable molds can be provided to produce different shapes and sizes. OEM mold customization is available based on your specifications.

Q4: Does this machine require specialized training to operate?

A5: Basic training is sufficient. The intuitive control panel and simple adjustment settings allow most operators to learn operation quickly, enhancing throughput with minimal technical support.